A few weeks back this big red school bus cruised past my house just after dinnertime, so the baby and I went pounding out the side door to chase it down. Turns out this is the Sol Food Mobile Farm: a standard International Blue Bird school bus that’s been completely refurbed as mobile living quarters and greenhouse (!!!) by some very pleasant folks from North Carolina. Dylan Hammond–a soft-spoken young carpenter and sustainable agriculture enthusiast–was kind enough to give me the grand tour, despite the fact that I came sprinting up out of the dusk demanding answers, barefoot, smelling of beer and stir fry, and bearing a groggy infant.

My dim snapshot gives you no sense how wonderful this bus is–and I’m somewhat of a connoisseur of half-cocked hipped school-bus schemes. The interior has been entirely gutted (saved for a few of the bench seats, reoriented to form part of the dinning and social area at the front of the bus), and outfitted not just with the necessities (four bunks, a kitchenette, the aforementioned greenhouse, which occupies the back third of the bus, where the roof has been replaced with curved acrylic), but also with *panache*: maple cabinets and hardwood floors (scrounged from some of Dylan’s construction gigs), a really roomy kitchen/dining/lounge with a small library, and a living roof of succulents (I even got to climb on top of the bus with my baby girl and check it out!) All of this, conveniently, rendered the former commercial vehicle a “camper” in the eyes of the law, meaning that none of the Sol Food folk needed to have CDLs to drive the thing.

The mods didn’t stop at the aesthetic and horticultural: the bus is also outfitted with a rain-water collection and recycling system (in theory–and in less drought-stricken seasons–all of their irrigation and potable water needs can be met by their onboard cisterns), and a full engine conversion so that they can–and do–run entirely on used fryer grease.

We’ve had a terribly dry summer here in Ann Arbor (like much of the country, we’re suffering historic drought conditions), so our garden’s showing has been pitiful. Meanwhile, the bus’s greenhouse had some of the largest, most productive tomato and cuke plants I’ve ever seen in my life. “People crassly imply we’re growing marijuana,” Dylan replied evenly when I asked what question he was most sick of fielding–and I hear where he’s coming from: What kind of idiots would build a grow operation that crosses state lines in plain sight? *sheesh*

The Sol Food folks are currently touring the US in a great 10,000(!!!) mile loop, spreading the gospel of hyper-local, totally sustainable, totally delicious agriculture. They’ve been on the road since June (they just hit Yellowstone!), and plan to continue rolling through most of December. If you’re so inclined, you can support their project here.

Category: Uncategorized

Public Speaking Advice from My Betters

I offer this (embedded below, from here: A Show with Ze Frank: How to Public Speaking) as a sort of corollary to what I wrote here (about the Worst Speech I Ever Gave). Ze’s method isn’t 100 percent my method, but we have a lot in common (specifically the edict to practice start-to-finish in a room alone, without stopping and starting or giving yourself redos)–and those were exactly the things I *didn’t* do in prepping for the Worst Speech Ever. Lived; learned.

My one addition to what Ze suggests here is this: As much as possible, avoid Giving a Speech, and instead Have a Conversation. By its nature, this is going to be a one sided conversation–because only one person in the room has a mic–but that’s OK; we’ve each been guilty of holding the floor past our turn. The trick is to talk to the people, not the mic: make eye contact, say specific sentences to specific people, try to LOL a specific guy. Just talk.

So, lessons learned–and shared with you! Enjoy!

What’s Dave-o Doing at Maker Faire Detroit?

Maker Faire Detroit is this weekend! I’m going to be there with an outdoor booth all Saturday and Sunday, and also giving a talk indoors (apparently in a replica of a drive-in movie theater[?!?]) on Sunday at 11:30am.

What will I be *doing* all weekend?

I’ll be helping folks rock out on cheap-as-hell musical instruments like these:

I’ll also be building and launching free water rockets with kids of all ages (while supplies last):

And that talk at the faux drive-in theater? I’ll walk you through how to build a musical synthesizer for about ~$10 and play it with your mouth.

I’ll also have scads of swag from my publisher, No Starch Press. If you’re at Maker Faire and want to connect, the best way to contact me is via Twitter, where I am @SquiDaveo–or just find my booth and say “Hey!”

See you this weekend!

Attention All Steampunks & Booknerds: All 111 Volumes(!!!) of Queen Victoria’s Diary Are Online NOW!

Free for your perusal until the end of July.

Queen Victoria’s Journals – Home Page

The interface is whack, but start browsing–almost at random–and you’ll find some startling and wonderful passages. To wit, this lil bit from page one of volume one, recounting one moment from Victoria’s 1832 journey to Wales via carriage:

This is the world that even the *richest little girl in all of the British Empire* saw and found remarkable, but by no means shocking or foreign. If you’re writing steampunk and this isn’t in there, then you’re doing it wrong.

See You at MAKER FAIRE DETROIT: JULY 28 & 29!

I’ll be at Maker Faire Detroit again this year, braving the searing rays of our terrible and merciless sun and shooting off water rockets like a mad man. I’ll have a “Cheap Thrills” booth outside, where I’ll be showing off under-$10-projects from SNIP, BURN, SOLDER, SHRED (as well as a couple of the new projects from my upcoming book of unconventional musical instruments), signing books, and making free water rockets with all comers (while supplies last). I’ll also be giving a half-hour, air-conditioned presentation on Sunday: “Your First Synthesizer: A Weird Little Noise-Toy You Can Build Tonight.”

I’ll be at Maker Faire Detroit again this year, braving the searing rays of our terrible and merciless sun and shooting off water rockets like a mad man. I’ll have a “Cheap Thrills” booth outside, where I’ll be showing off under-$10-projects from SNIP, BURN, SOLDER, SHRED (as well as a couple of the new projects from my upcoming book of unconventional musical instruments), signing books, and making free water rockets with all comers (while supplies last). I’ll also be giving a half-hour, air-conditioned presentation on Sunday: “Your First Synthesizer: A Weird Little Noise-Toy You Can Build Tonight.”

My long-time co-conspirator Fritz Swanson will also be at Maker Faire (his first ever!) demoing “Letter-press Printing: Data Distribution the 19th Century Way,” as will my pal Amy Stevenson, teaching at-home artisanal paper making. See you there!

Reduced rate early-bird tickets are still available, or so I’m told (click through the Maker Faire Detroit link for details).

Make a Log into a Stove

This won’t come up often, but it’s one to keep in your vest pocket, just in case:

Stuff in some newspaper into the cracks as deep as you can get it, leaving a wick at the bottom, and light it up.

That’s all there is to it—the log burns from the inside out, and you have a simple, handmade stove….TA DA

~~ Tonya O’Tinger prostaff.

(via the Homesteading / Survivalism Facebook Page and http://www.homesteadingsurvivalism.com/)

My God, These Are Lovely Motorized Bicycles

The Derringer Bespoke Collection. — derringer

I don’t usually go in for the motor-assisted bicycle thing, but if I were to find a few grand lying in the street, I’d drop it on one of these in a heartbeat. (Well, first I’d pay my summer property taxes, so if I found a buncha grand lying in the street . . . well, you get it, you get it. Just saying’: Damn, these are *lovely!*)

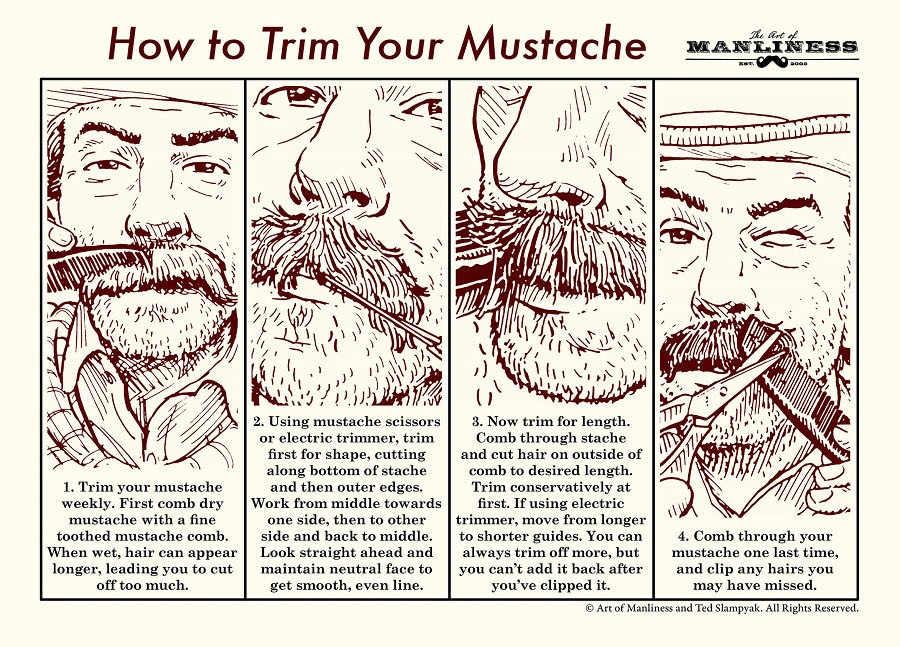

How to Trim Yr ‘stache

Clearly more useful for some readers than others–but I’m one of the “some,” and this method differs somewhat from mine (I’ve never done Step #3, and am still a little ambivalent about it).

(via the oft enjoyed Art of Manliness)

Cork, Wine Bottles, and Food-Grade Wood: Fixing Broken Appliances and Making Them Beautiful

FACT: While many of our home gadgets are complex microcomputers that are basically beyond the ken, let alone skills, of average folk like you and me, the vast bulk of our appliances (even the heavy ones, like your stove or dishwasher) are still simple electromechanical devices heart. If you can replace a fuse, recognize an obviously burned out connection, or re-attached a slipped belt, you can keep that “broken” vacuum or toaster humming for years to come. You can teach a grade schooler to do this safely.

COMPLICATION: While the electrical *guts* of our devices continue to be mid-twentieth century technology, the *cases* are almost invariably customized, injection molded plastic pieces of crap held together with glue, break-away tabs, and funky-ass screws designed to drive average folk *insane.*

PROBLEM: Plenty of devices have perfectly workable guts, but broken cases, and those cases can’t be readily repaired.

SOLUTION: Make your own replacement enclosures.

These are so, so lovely *and* well within the reach of Average Joes and Janes. Yes, this guy is using a fancy CNC, but he’s also planning to roll out this system to the UK equivalent of the Salvation Army. If you’re just fixing your blender or rice cooker, then you can easily work the wood with hand tools. What’s brilliant here is that he’s using *cork.* Cork is *great* for kitchen appliances: You can carve it with a drill and hobby knife, it will put up with lots of knocking about and getting wet, and it can easily mesh with the curved-line aesthetics of modern appliances (i.e., you can replace *parts* of a FUBARed case, instead of having to rebuild the whole thing with food-grade wood from for local lumber yard). I love it!

Short-circuit : Gaspard Tine-Beres

. . .

My Coffee-maker, kettles and toaster, are made out of re-used components, and factory seconds glassware such as wine bottle and chemistry beakers, in order to take advantage of it’s ubiquity, and standardized dimensions. The main structure is made out of natural cork for it’s waterproof, anti-bacterial and insulation properties. This design required no mould and can be easily adapted, upgraded, or repaired as required.

CNC Routing Is a Lovely Process

A CNC router is a machine that uses a computer to control a spinning bit (“CNC” stands for “computer numerical control”) in order to precisely carve materials (usually wood or metal, although you can basically carve anything that’s rigid-ish: I’ve seen folks route fiberglass, acrylic, styrofoam, ice, and even hunks of melon). Any shape you can map with a computer can be carved by the appropriate CNC router.

In my humble, CNC routers are just lovely to watch, in and of themselves. If robots had to invented ballet, it would look like this. That the process is being used to produce a Möbius strip lends the whole think a little extra cognitive luster. I especially like that they elected to retain–and even accentuate–the milling artifacts of the CNC process; lends just the right touch of wabi-sabi, the degree to which a “perfect” automated process still leaves signs of its having passed this way.

mobiprize | rvtr